Paver Installation Compaction: A Comprehensive Guide

Introduction

Pavers, also known as interlocking concrete pavers (ICPs), are a versatile and durable paving material used in a wide range of applications, from driveways and patios to walkways and pool decks. Proper installation of pavers is crucial for ensuring their longevity and performance, and one of the most important aspects of installation is compaction. This article provides a comprehensive guide to paver installation compaction, covering the principles, methods, and equipment involved.

Principles of Compaction

Compaction is the process of increasing the density of a material by reducing the air voids between its particles. In the context of paver installation, compaction is essential for achieving a stable and level surface that can withstand heavy loads and resist settlement. Compaction also helps to prevent water infiltration and frost damage.

The degree of compaction required for pavers depends on several factors, including:

- Paver type: Different types of pavers have different compaction requirements.

- Base material: The type of base material used under the pavers can affect the level of compaction needed.

- Traffic load: The anticipated traffic load on the paver surface will determine the required compaction level.

Methods of Compaction

There are two main methods of compacting pavers:

- Hand compaction: This method is typically used for small areas or areas with limited access. It involves using a hand tamper or plate compactor to manually compact the pavers.

- Machine compaction: This method is more efficient and suitable for larger areas. It involves using a vibratory plate compactor or roller to compact the pavers.

Equipment for Compaction

The following equipment is typically used for paver installation compaction:

- Hand tamper: A handheld tool with a flat or rounded base used for manual compaction.

- Plate compactor: A motorized machine with a flat base that vibrates to compact the pavers.

- Roller: A motorized machine with a cylindrical drum that rolls over the pavers to compact them.

Compaction Procedure

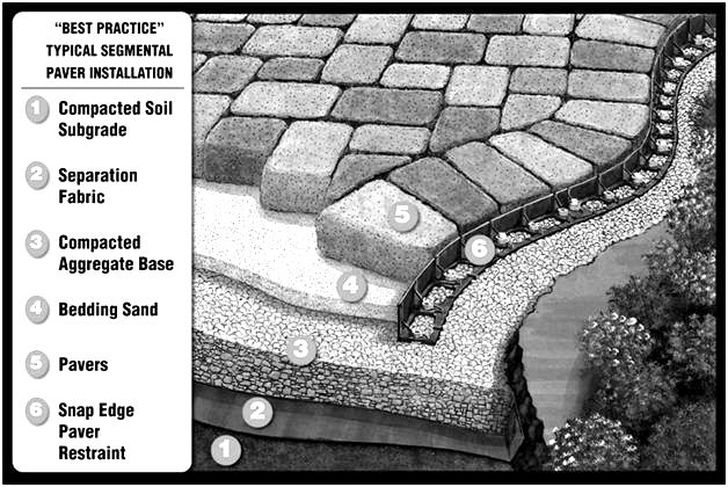

The compaction procedure for pavers involves the following steps:

1. Prepare the Base

- Excavate the area to the desired depth and grade.

- Install a base material, such as crushed stone or gravel, and compact it to the required level.

2. Set the Pavers

- Lay the pavers on the base material in the desired pattern.

- Use a rubber mallet to tap the pavers into place and ensure they are level.

3. Compact the Pavers

- Hand compaction: Use a hand tamper or plate compactor to manually compact the pavers. Start at the edges and work your way towards the center.

- Machine compaction: Use a vibratory plate compactor or roller to compact the pavers. Start at the lowest compaction setting and gradually increase the pressure as needed.

4. Check the Compaction

- Use a level to check the surface of the pavers for levelness.

- Use a compaction gauge to measure the density of the compacted pavers.

5. Repeat Compaction

- If the compaction is not sufficient, repeat the compaction procedure until the desired level of compaction is achieved.

Compaction for Different Paver Types

Different types of pavers have different compaction requirements. Here are some general guidelines:

- Concrete pavers: Require moderate compaction.

- Clay pavers: Require heavy compaction.

- Permeable pavers: Require light compaction.

Compaction for Different Base Materials

The type of base material used under the pavers can also affect the level of compaction required. Here are some general guidelines:

- Crushed stone: Requires heavy compaction.

- Gravel: Requires moderate compaction.

- Sand: Requires light compaction.

Compaction for Different Traffic Loads

The anticipated traffic load on the paver surface will determine the required compaction level. Here are some general guidelines:

- Light traffic (pedestrians, bicycles): Requires light compaction.

- Medium traffic (cars, light trucks): Requires moderate compaction.

- Heavy traffic (heavy trucks, buses): Requires heavy compaction.

Troubleshooting Compaction Issues

If you encounter any issues during paver installation compaction, here are some troubleshooting tips:

- Pavers are not level: Use a level to check the surface of the pavers and adjust them as needed.

- Pavers are loose: Increase the compaction pressure or repeat the compaction procedure.

- Pavers are cracked: Reduce the compaction pressure or use a different compaction method.

- Base material is not stable: Excavate the area and replace the base material with a more stable material.

Conclusion

Proper compaction is essential for ensuring the longevity and performance of paver installations. By following the principles, methods, and equipment outlined in this guide, you can achieve a stable, level, and durable paver surface that will withstand the test of time.